Localized Supply Chain

Local Procurement

In addition to actively localizing technology and equipment, THSRC has implemented a localized procurement strategy on the premise of ensuring the safety and quality of equipment. This strategy not only decreases reliance on foreign suppliers, but also reduces carbon footprint from overseas transportation, achieving the dual effect of balancing procurement costs and effectively shortening the lead time for equipment conversion. At the same time, local suppliers of rail transportation industry can take this opportunity to obtain certification of the international railway industry standard quality system, greatly enhancing the image and popularity of the domestic rail transportation industry.

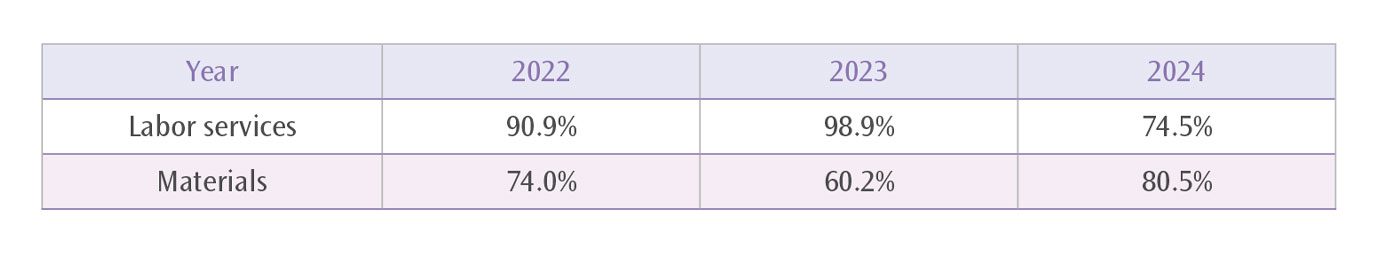

In 2024, the total amount of material purchases conducted by THSRC was approximately NT$3.3 billion, where the amount of procurement from local suppliers accounted for 80.5% of the total amount. Meanwhile, the amount of labor service procurement in 2024 exceeded NT$12.7 billion, of which 74.5% came from local service procurement. The figures as at below:

Local Procurement Amount Ratio

In order to achieve sustainable procurement's goal, we have followed the "Green Procurement Declaration for Private Enterprises and Group" announced by the Ministry of Environment of the Executive Yuan, giving priority to the procurement of products and services with eco-labels, green labels, carbon footprint labels, and carbon reduction labels. In 2024, the total amount of green procurement reached NT$360 million, covering administrative supplies, business machine supplies, drinking fountains, electric refrigerators, and green building materials (such as energy labeling equipment and products with carbon footprint certification). Moreover, since THSRC has obtained carbon label certification, expenses incurred from employees traveling for business by HSR were also included in the green procurement amount, demonstrating our active decarbonization efforts across operational processes and the value chain.

Local Development

In its efforts to promote the growth of local rail technologies and capabilities, THSRC is committed to localizing the rail supply chain. Through collaborations with government research projects and universities, we are expanding our domestic supplier base and deepening the local supply chain for high-speed rail materials and components. In 2024, we successfully completed 104 alternative sourcing cases, after visiting a total of 250 local suppliers. Through joint work with 136 alternative materials-developing suppliers from 2011 to 2024, we were able to save approximately NT$4.1 billion. In addition to expanding our recruitment of manufacturers, THSRC has also broadened our cooperation with industry, government, academia, and research to jointly developed high-speed railway equipment and system innovation technology. Through these efforts, we have contributed to the localization of railway transportation and achieved our goal of "Localization of Domestic Vehicles." Relevant cooperation projects in 2024 include:

THSRC has launched a new 5-year medium and long-term plan from 2023 to create a higher-quality travelling environment for passengers, through working with domestic manufacturers. In 2024, we successfully developed new passenger information display systems and replace the original LED screen form with a 4K high-quality full-color LCD screen, we plan to add passenger elevators at stations, improve train restroom spaces, and continue to increase the localization of maintenance materials in 2025.

Local Business

To promote the growth of local industries and capitalize on local business opportunities, THSRC has established station markets and local production halls throughout its operations in Taiwan. These facilities support the production of local raw materials and creating local employment opportunities through concrete actions such as low rental fee for local business.